Power Fasteners Wedge Bolt For Concrete Forms

Galvanized Fasteners Wedge Bolt Firmware designed for consistent performance in cracked and uncracked concrete

Bolt For Concrete Forms are suitable for base materials including normal weight, sand lightweight concrete, concrete on steel plate and grouted concrete masonry.

Common applications for Wedge Bolt include structural connections such as beam and column anchors

Fasteners Nominal drill bit size is the same as the anchor diameter

Wedge can be installed through standard fixing holes

Some tips and tricks for Power Fasteners Wedge Bolt For Concrete Forms

Q:Wedge anchors -- which I am presently using to better secure the mudsill to the foundation here in earthquake-prone California -- they say to drill the hole to the diameter of the wedge bolt. However, it seems hard to hammer the bolt in unless you "ream" the hole just a bit wider --to accommodate the wedge... Is this OK or will doing this affect the maximum "grip" strength" of the bolt ? When I tighten, they seem to be in there pretty good, but I was just wondering if this will affect the performance when the 'BIG ONE' finally hits ..

A:No, you're doing it right. The wedge anchors should be quite tight in the hole to better secure them.

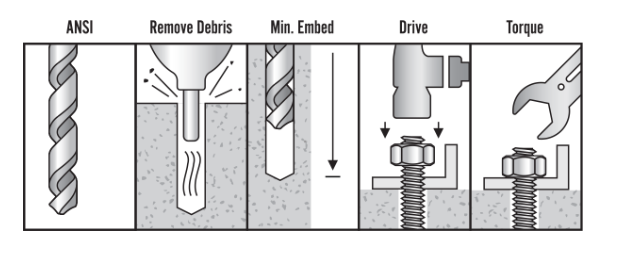

Wedge Anchor & Decking Post Base Installation

Clean out the hole before installing the bolt. Most of my bolting involves life-critical applications. 'Dusty' holes have caused a few deaths, when the expansion ring of the bolt tightened against rock/cement powder instead of the actual material. It 'feels' snug to a hand tug, even to a bit of prying. But large forces (In one case barely >50N) can pull the bolt out of the hole! BRUSH and BLOW out the hole before installation.

1: Drill the hole slightly deeper than the entire length of the anchor. Why? Because if you remove the anchored item later in life you can hammer the anchor down into the hole flush with the concrete and not have to use an angle grinder and leave a sharp protrusion or grind up and damage the floor in the process (especially important on epoxy finished floors)

2: Before hammering the anchor into the floor install the washer and thread the nut to the depth you would like. Now you do not have to worry about knocking the anchor too deep.

3: If you are finding the anchor hard to drive into the concrete, thread a bolt flush on the anchor. You now have a large striking surface and you don't risk ballooning the top and making it impossible to get a nut onto it if you accidentally strike the edge with your hammer.

4: Last tip, if possible setup your product to be anchored first, then drill your hole and install the anchor directly through the product to be anchored. Now you can drive the anchor in and tighten it up without having to lift the product over the exposed bolt. This is especially handy when anchoring something like a 1000 pound air compressor or machinery with multiple anchor points.

About what our customers have to say about us

Why Choose Us?

Please contact sales below and they will answer all your questions!!!